| Standard Material of Construction: |

| 1/ 2 |

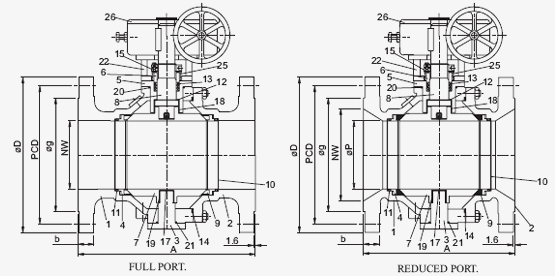

Body/ Side Piece |

WCB, CF8, CF8M, CF3, CF3M, F304, 316, CN7M, Inconel 625(UNS N06625), Inconel 825(UNS N08825), Duplex(4A), Super Duplex(5A & 6A), Nickel Aluminum Bronze(AB2), Bronze(B62), LCB, LF2. |

| 3/ 4/ 5 |

Trunion/ Seat

Retainer/ Stuffing Box |

WCB, CF8, CF8M, CF3, CF3M, F304, F316, CN7M, Inconel 625(UNS N06625), Inconel 825(UNS N08825), Duplex(4A), Super Duplex(5A & 6A), Nickel Aluminum Bronze(AB2), Bronze(B62), LCB, LF2 |

| 6 |

Gland |

ANSI410, 304, 316, 316L, 304L, MONEL, ALLOY20, HAST-B, C. |

| 7 |

Ball |

ANSI410, 304, 316, 316L, 304L, MONEL, ALLOY20, HAST-B, C, Inconel 625(UNS N06625), Inconel 825(UNS N08825), Duplex(4A), Super Duplex(5A & 6A), Nickel Aluminum Bronze(AB2), Bronze(B62), LCB, LF2. |

| 8 |

Stem |

ANSI410, 304, 316, 316L, 304L, MONEL, ALLOY20, HAST-B, C. |

| 9 |

Seat |

PTFE, GFT, CFT, Nylon, Peek. |

| 10 |

Seat Ring |

A105, WCB, CF8, CF8M, CF3, CF3M, F304, F316, CN7M, Inconel 625(UNS N06625), Inconel 825(UNS N08825), Duplex(4A), Super Duplex(5A & 6A), Nickel Aluminum Bronze(AB2), Bronze(B62), LCB, LF2. |

| 11 |

"O" Ring |

Viton. |

| 12 |

Stem Washer |

GFT. |

| 13 |

Gland Packing |

PTFE, Grafoil. |

| 14 |

Body Seal |

PTFE, Grafoil, SWG. |

| 15 |

Check Nut |

Carbon steel, AISI 304. |

| 16 |

Thrust Washer |

GFT. |

| 17 |

Body Stud/Nut |

B7/2H, B8/B8M, B7M/2HM(With Elctro Zinc Plating). |

| 18/19 |

Stuffing Box/ Trunion Bearing |

AISI 316 Backed PTFE. |

| 20/21 |

Stuffing Box/ Trunion Seal |

Grafoil, PTFE. |

| 22 |

Bracket |

Carbon steel. |

| 23 |

Gland Nut |

Carbon steel. |

| 23 |

Belleville Spring |

Spring Steel. |

| 25 |

Antistatic Spring |

Stainless Steel, Inconel. |

| 26 |

Gear Box |

Cast Iron. |