| General Design & Manufacturing | : | BS EN ISO 17292 / API-6D |

| Valve Dimensions | : | ASME B16.10/ ASME B16.5 |

| Valve Inspection & Testing | : | BS EN 12266-1 |

| : | Hydro Shell: 32 kg/sq.cm | |

| : | Seat Test: 22 kg/sq.cm | |

| : | Air Seat: 7 kg/sq.cm | |

| Special Features | : | Fire Safe to API-607 |

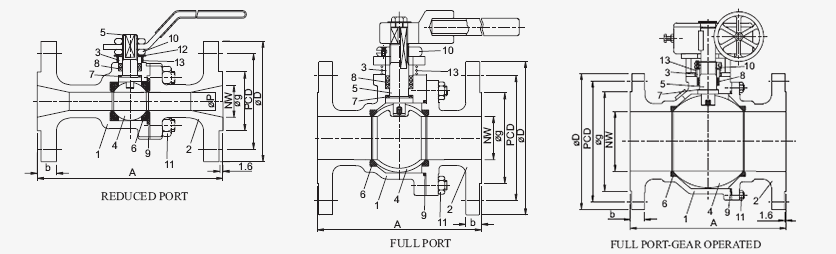

| 1. | Valve type | : | Floating Design Ball Valve. |

| 2. | Body type | : | 2 PC OR 3 PC |

| 3. | Seat type | : | Soft Seated. |

| 4. | End Connection | : | Flanged End. |

| 5. | Size range | : | 15 NB to 300 NB |

| 6. | Pressure rating | : | Class 150 |

| 7. | Seat leakage | : | Class VI - soft seat. |

| 8. | Operation | : | Hand lever/ Gear / Actuator (Electrical / Pneumatic). |

| Size | A | NW | ΦP | ΦD | b | Φg | PCD | Hole | No.of Holes |

|---|---|---|---|---|---|---|---|---|---|

| 15 | 108 | 13 | 9.5 | 89 | 11.5 | 35 | 60.5 | 16 | 4 |

| 20 | 117 | 19 | 13 | 98 | 13 | 43 | 70 | 16 | 4 |

| 25 | 127 | 25 | 19 | 108 | 11.5 | 51 | 79.5 | 16 | 4 |

| 32 | 140 | 32 | 25 | 117 | 13 | 64 | 89 | 16 | 4 |

| 40 | 165 | 38 | 32 | 127 | 14.5 | 73 | 98.5 | 16 | 4 |

| 50 | 178 | 50 | 38 | 152 | 16 | 92 | 120.6 | 20 | 4 |

| 65 | 190 | 65 | 50 | 78 | 17.5 | 105 | 139.7 | 20 | 4 |

| 80 | 203 | 76 | 58 | 191 | 19.5 | 127 | 152.4 | 20 | 4 |

| 100 | 229 | 98 | 76 | 229 | 24 | 157 | 190.5 | 20 | 8 |

| 150 | 267 | 148 | 98 | 279 | 25.5 | 216 | 241.3 | 23 | 8 |

| 200 | 292 | 198 | 144 | 343 | 29 | 270 | 298.4 | 23 | 8 |

| 250 | 330 | 254 | 187 | 406 | 30.5 | 324 | 362 | 26 | 12 |

| 300 | 610 | 305 | 228 | 483 | 32 | 381 | 431.8 | 26 | 12 |

| Standard Material of Construction: | ||

|---|---|---|

| 1 | Body | A105, WCB, CF8, CF8M, CF3, CF3M, F304, F316, CN7M, Inconel 625(UNS N06625), Inconel 825(UNS N08825), Duplex(4A), Super Duplex(5A & 6A), Nickel Aluminum Bronze(AB2), Bronze(B62), LCB, LF2. |

| 2 | Side Piece | A105, WCB, CF8, CF8M, CF3, CF3M, F304, F316, CN7M, Inconel 625(UNS N06625), Inconel 825(UNS N08825), Duplex(4A), Super Duplex(5A & 6A), Nickel Aluminum Bronze(AB2), Bronze(B62), LCB, LF2. |

| 3 | Gland | ANSI410, 304, 316, 316L, MONEL, ALLOY20, HAST-B, C. |

| 4 | Ball | ANSI410, 304, 316, 316L, MONEL, ALLOY20, HAST-B, C., Inconel 625(UNS N06625), Inconel 825(UNS N08825), Duplex(4A), Super Duplex(5A & 6A), Nickel Aluminum Bronze(AB2), Bronze(B62), LCB, LF2 |

| 5 | Stem | ANSI410, 304, 316, 316L, MONEL, ALLOY20, HAST-B, C. |

| 6 | Seat | PTFE, GFT, CFT / Peek / Delrin, Nylon. |

| 7 | Steam Seal | GTF |

| 8 | Gland Packing | PTFE, Grafoil. |

| 9 | Body Seal | PTFE, Grafoil. |

| 10 | Gland Nut | Carbon steel. |

| 11 | Body Stud/Nut | B7/2H, B8/B8M, B7M/2HM(With Elctro Zinc Plating). |

| 12 | Belleville Spring | Spring steel |

| 13 | Antistatic Spring | Stainless Steel, Inconel |